Next generation ZINCALUME® aluminium/zinc/magnesium alloy coated steel complies with AS 1397:2011 G550, AM125 (550 MPa minimum yield stress, 125 g/m² minimum coating mass).

COLORBOND® steel is prepainted steel for exterior roofing and walling. It is the most widely used. The painting complies with AS/NZS 2728:2013 and the steel base is an aluminium/zinc alloy-coated steel complying with AS 1397:2011. Minimum yield strength for CUSTOM ORB is G550 (550 MPa). Minimum coating mass is AM100 (100 g/m²).

COLORBOND® Metallic steel is prepainted steel for superior aesthetic qualities displaying a metallic sheen.

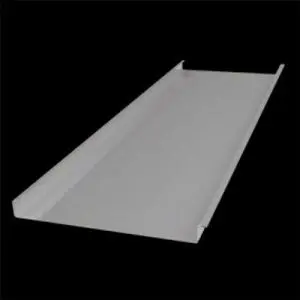

ARCHITECTURAL CLADDING

Zincalume and Colorbond are exceptional materials, used for the cladding of walls, adding beautiful aesthetic advantages, and insulating envelopes around the structure, slashing energy consumption percentages of the building.

Next-generation ZINCALUME® aluminium/zinc/magnesium alloy coated steel complies with AS 1397:2011 G550, AM125 (550 MPa minimum yield stress, 125 g/m² minimum coating mass).

Zinc is rated, globally, among the top performers of building materials for sustainability and longevity. It is the 24th most abundant element in the earth’s crust.* It is weatherproof and withstands UV rays, rust and corrosion as it is a non-ferrous metal. The zinc cladding develops its own protective layer of zinc hydroxy-carbonate, repelling moisture and free radicals and can regenerate itself if slightly damaged. It withstands extremely hot and extremely cold weather conditions. The manufacturing process has a low energy requirement, and the finished product is fully recyclable with a life expectancy of up to 100 years.

COLORBOND® steel is prepainted steel for exterior roofing and walling as well as interior use. It is the most widely used roofing material in Australia and is very cost-effective. Its superior aesthetic qualities display a metallic sheen and architects use Colorbond to create design outcomes that are unique but not extreme.

It is manufactured in Australia with a process that starts with the base being coated in BlueScope’s industry-leading, Activate®* coating technology, providing greater resistance to weather, free radicals and corrosion. A thin, adhesive catalyst layer is applied in between to enhance the traction and adhesion of additional coatings. Then a corrosion inhibitor is baked on and finally a highly engineered topcoat, exterior-grade paint is baked on. This delivers chipping, flaking and blistering resistance and greater longevity.

*Activate® technology is not available for COLORBOND® Stainless steel, COLORBOND® Coolroom steel, and COLORBOND® steel products with a galvanised steel substrate.

The painting complies with AS/NZS 2728:2013, and the steel base is an aluminium/zinc alloy-coated steel complying with AS 1397:2011. Minimum yield strength for CUSTOM ORB is G550 (550 MPa). Minimum coating mass is AM100 (100 g/m²).